LOOMIS PRODUCTS ISOSTATIC WET BAG PRESSES

In this process, the powder is filled into a flexible form, usually rubber or polyurethane, and tightly sealed. The mold is then immersed in the liquid (water-oil emulsion) within the pressure vessel. Isostatic pressure is then exerted on the entire outer surface of the mold, which compresses the powder into a solid body (green part).

Advantages of isostatic wet bag press:

Uniform strength and density

Homogeneous microstructure

Uniform shrinkage

Complex shapes and high dimensional accuracy

Reduced finishing

Low mold cost

Wide variety of materials

Very high pressing pressures

Fast pre-filling and emptying times

- Press pressures of over 400 MPa (4,000 bar)

- Pressure vessel inner diameter: from 75mm to over 1,200 mm

- Pressure vessel working lengths: from 300mm to over 4,000 mm

- Press medium of the pressure vessel: Water/Oil Emulsion

- Fully automated, programmable pressing cycle (open / open)

- Integrated mold rack for automatic feeding/unloading of the molds

- Variable press parameters for pressure build-up speed / pressure dwell time / decompression / holding or switching stages

- Storage of product-specific pressing parameter recipes

- Hydraulic lifting and closing mechanism for the upper closure

- Automatic de-airing valve

- Fast pre-filling and emptying of the pressure vessel via high-volume high pressure pilot operated check valve

- Free programmable HD decompression valve (servo-controlled) enables precise and variable decompression stages

- Selection of different high-pressure generators (HD pressure multipliers / HD triplex plunger pumps)

- Extensive fluid reservoir and pumping systems with multiple filtration of the press fluid

- Fully automatable press mold handling with conveyor carousel via filling station / mold washing cabin / automatic loading / unloading into / from the pressure vessel to the demolding station.

- Easy operation via plain text instructions

- Clear process displays

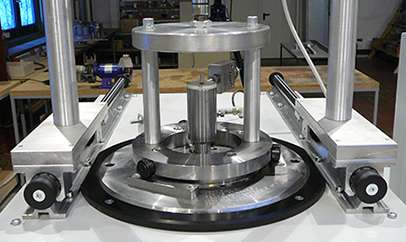

ISOSTATIC LABORATORY PRESSES –

as wet and dry bag presses

Cutting-edge technology in a small format

LOOMIS PRODUCTS isostatic laboratory presses are the ideal solution for process/material testing and the production of smaller series.

Custom sizes available

Variable press parameters for pressure build-up speed / pressure holding time / decompression / holding or switching stages

Lifting and closing mechanism for the upper closure

Automatic de-airing valve

Fast pre-filling and emptying of the pressure vessel via high-volume pilot operated check valve

Adjustable high pressure decompression valve enables gentle and variable decompression speeds

Selection of different high-pressure generators (air-driven high-pressure pump / hydraulic pressure multiplier

Easy operation via plain text instructions